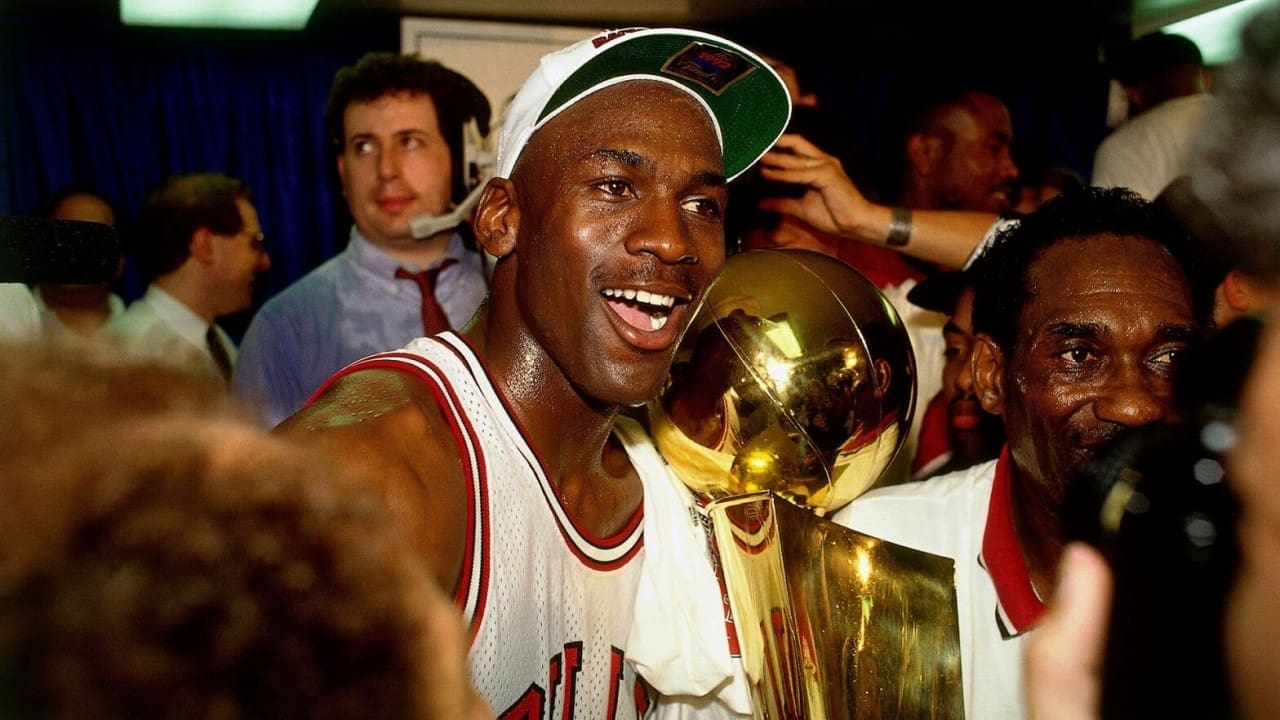

Michael Jordan, one of the greatest basketball players of all time, is famously quoted as saying: “I’ve missed more than 9,000 shots in my career. I’ve lost almost 300 games. Twenty-six times, I’ve been trusted to take the game-winning shot and missed. I’ve failed over and over and over again in my life. And that is why I succeed.” This iconic example underscores a critical truth: failure is not the enemy of success but its necessary companion.

In my experience with organizations across the globe, failure often carries a heavy stigma. Many organizations, teams, and individuals shy away from the possibility of making mistakes. But what if we could flip the script? What if we embraced failure as an essential part of the journey toward success? This idea is the cornerstone of our upcoming Lean Solutions Podcast series, where we dive deep into reframing failure through the lens of lean thinking and continuous improvement.

Mark Graban’s Lessons on Failure

Mark Graban’s podcast, My Favorite Mistake: Business Blunders, Lessons Learned, and Paths to Success, offers a wealth of insight into how failures can serve as pivotal learning moments. His book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation, expands on this idea, showing how leaders and organizations can build environments where learning from mistakes is the norm rather than the exception.

One example Mark shares comes from the healthcare industry, where a hospital reduced medication errors by embracing transparency and learning from mistakes. Rather than punishing individuals for errors, the organization implemented a fail-forward culture that analyzed mistakes, improved processes, and ultimately enhanced patient safety.

Lean Thinking: Turning Failure into a Teacher

In 2020, The Lean Enterprise Institute released an article titled, “It’s Only A Failure If You Don’t Learn.” In this article, the author highlights that failure only becomes detrimental when we fail to learn from it. The author begins with a story from Katie Anderson‘s book, “Learning to Lead, Leading to Learn,” where Isao Yoshino (a 40-year Toyota leader and a former NUMMI training manager based at Toyota headquarters in Japan) worked for years developing a water-ski boat business for Toyota, and while the business ultimately failed, he learned many key lessons from this experience.

Lean thinking emphasizes controlled experimentation—deliberate tests designed to uncover valuable insights without risking catastrophic outcomes. By adopting this mindset, organizations can continuously improve while minimizing fear.

SO WHY THIS EMPHASIS FROM SO MANY PEOPLE ON EMBRACING FAILURE?

Why do so many thought leaders, organizations, and innovators emphasize the importance of embracing failure? The answer lies in the undeniable link between failure and growth. In an environment where perfection is prioritized over progress, innovation stalls. Leaders like Michael Jordan and countless organizations recognize that failure is not a reflection of incompetence but a necessary ingredient in the recipe for success.

First, failure fosters resilience. When individuals and teams encounter setbacks, they develop the perseverance needed to overcome future obstacles. For example, a tech startup that failed to secure funding in its first round learned valuable lessons about pitching, which they used to successfully secure investors in a later attempt. Without that initial failure, the team wouldn’t have honed their approach.

Second, failure drives innovation. Many groundbreaking ideas stem from experiments that didn’t go as planned. Consider Thomas Edison, who famously said, “I have not failed. I’ve just found 10,000 ways that won’t work.” Each failed attempt brought him closer to the invention of the light bulb, an innovation that changed the world.

Finally, embracing failure cultivates a culture of learning and improvement. When organizations view mistakes as opportunities to grow rather than reasons for punishment, employees feel empowered to take calculated risks. This shift leads to more creative problem-solving, higher engagement, and continuous improvement. In healthcare, for example, hospitals that encourage open discussions about errors see marked improvements in patient safety and care outcomes.

Lean Solutions Podcast Highlights Rethinking Failure

Be sure to subscribe to The Lean Solutions Podcast on your favorite podcast platform because then you will receive updates when new episodes come available. Our upcoming Lean Solutions Podcast episodes explore various aspects of failure and learning:

- Episode 1: Rethinking Failure. We shift the narrative, positioning failure as a teacher, not an enemy. Practical examples from lean practitioners will show how reframing failure leads to breakthroughs.

- Episode 2: Learning from the Trenches. Stories from industries like manufacturing, government, and healthcare reveal how leaders overcame challenges. Lean principles, such as root-cause analysis and PDCA cycles, turned failures into stepping stones for success.

- Episode 3: Building a Fail-Forward Culture. This episode explores the tools and practices that foster psychological safety, encourage experimentation, and celebrate both small wins and lessons learned from setbacks.

Five Ways to Embrace Learning from Failures

- Reframe Failure as Feedback. Instead of seeing failure as a dead-end, view it as a stepping stone. When a team conducted a kaizen event that initially failed to deliver the expected results, they analyzed the data, adjusted their approach, and ultimately doubled their productivity.

- Start with Controlled Experiments. Embrace small, low-risk experiments. For example, a retail company piloted a new inventory system in one store before scaling it across the entire chain. The controlled approach allowed them to identify flaws without widespread disruption.

- Celebrate Small Wins and Lessons Learned. Create rituals for recognizing not just achievements but also insights gained from setbacks. One team introduced a “failure board” to highlight lessons learned and new ideas generated from experiments gone awry.

- Cultivate Psychological Safety. Build an environment where employees feel safe to speak up about mistakes. A manufacturing company found that open discussions about defects led to a 30% improvement in quality, simply because workers were empowered to share and solve problems together.

- Incorporate Reflection into Processes. Use lean tools like A3 thinking or retrospectives to reflect systematically. For example, after a failed product launch, a tech company’s team conducted a thorough A3 analysis, which revealed key gaps in market research and led to a more successful re-launch.

Creating a Learning Culture

The goal isn’t to encourage failure but to create a culture where learning thrives. Controlled experimentation—a hallmark of lean thinking—balances risk and innovation. By creating processes and spaces for reflection, leaders can foster continuous improvement while maintaining accountability.

As we embark on this podcast series, we invite you to join the conversation. Listen, reflect, and share your experiences with failure. Together, we can transform setbacks into opportunities for growth and success. Tune in to the Lean Solutions Podcast and let’s rethink what it means to fail.

0 Comments